Influence of Axial Movement on Fatigue of Profile® Ni-Ti Rotary Instruments: an in vitro evaluation

DOI:

https://doi.org/10.17305/bjbms.2010.2703Keywords:

axial movement, fatigue, instrument separation, life-span, Ni-Ti instruments, simulated canalsAbstract

The aim of this study was to evaluate the influence of the axial movement and the angle of curve (in degrees) on fatigue of nickel-titanium (Ni-Ti) ProFile’ rotary endodontic instruments.

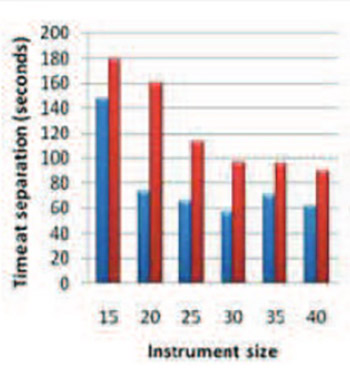

Ni-Ti ProFile’ rotary instruments (Maillefer SA, Ballaigues, Switzerland), 25 mm long in the range of ISO size 15 to 40 with two tapers (0.4 and 0.6) were evaluated. They are divided in two groups: the instruments with axial movement and those without axial movement. The system used to test the fatigue is maintained in mechanical conditions as close as possible to the clinical situation. The axial movement is in the order of 2mm in corono-apical direction with a frequency of 1Hz. The concave radii incorporating a notched V-form for guiding the instruments were: 5; 7,5 and 10 mm. The rotary system is mounted on an electric handpiece and rotated at 350 rpm speed as recommended by the manufacturers. The instruments are rotated until their separation, and the time, in seconds, is recorded. Statístícal evaluation is undertaken using a two-way t-test to identify significant differences between variables in the study (p <0,05).

We found significant statistical difference (p<0,05) between Ni-Ti engine drive ProFile’ instruments incorporating an axial movement and the instruments without axial movement with the same radius of curvature, size and taper.

The incorporation of the axial movement increases significantly the life-span of the ProFile’ rotary instruments. This should reduce the risk of the instrument separation during the endodontic treatment

Citations

Downloads

Published

Issue

Section

Categories

How to Cite

Accepted 2017-11-23

Published 2010-05-20